Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

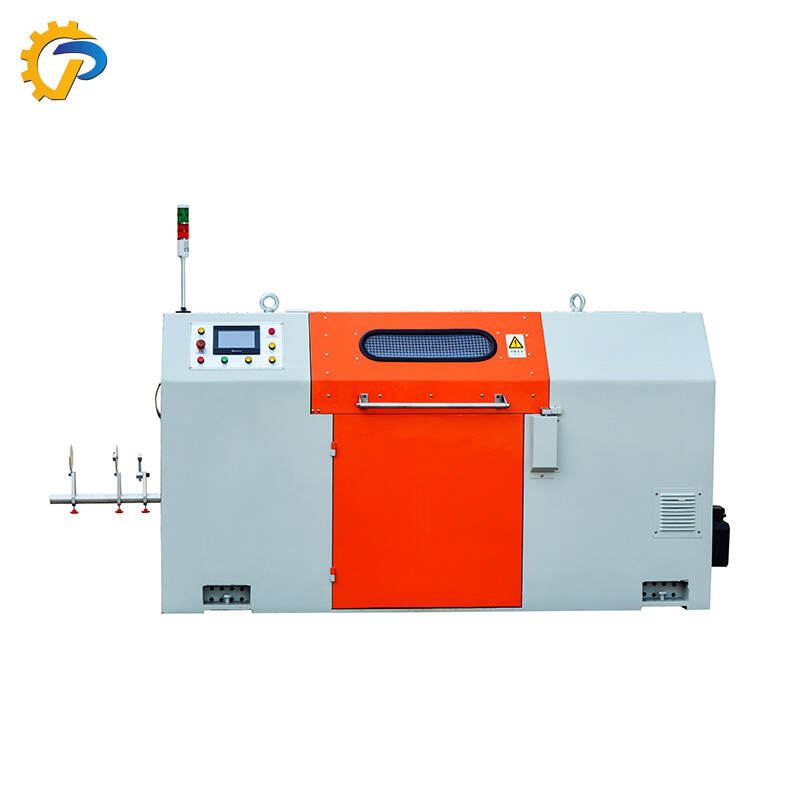

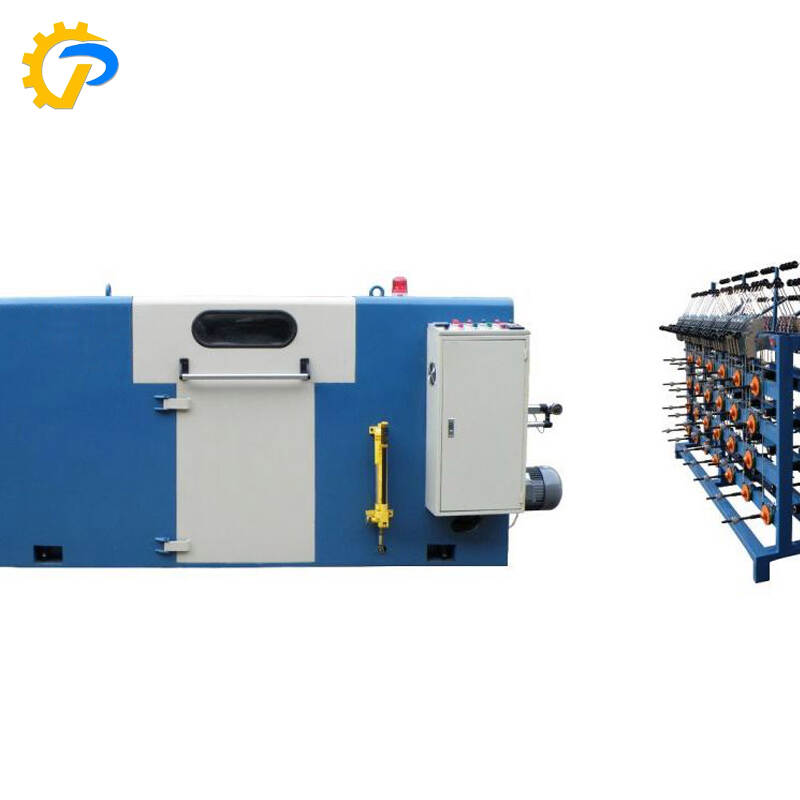

630 bunching machine

The 630 Bunching Machine is a high-efficiency solution engineered for precision cable twisting in modern wire and cable manufacturing lines. Built for durability, accuracy, and user safety, this machine integrates advanced control systems and tension management for consistent performance. Ideal for both small and large-scale production environments, it ensures optimal bunching of multiple wire strands with minimal downtime.

Product Features

Dual-Gear Pitch Control System

This machine features a dual-gear pitch adjustment mechanism, enabling accurate and consistent control over wire pitch for various cable specifications.

Heavy-Duty Welded Frame Construction

Constructed from Q235 steel with an annealed, stress-relieved frame, the 630 Bunching Machine offers excellent structural integrity and vibration resistance during high-speed operation.

Intelligent HMI Control Panel

The integrated human-machine interface (HMI) allows operators to set, monitor, and record key parameters such as wire count, diameter, tension, and line speed for precise production control.

Automatic Tension Control System

Equipped with a magnetic powder clutch, this system maintains constant tension from empty to full spool, ensuring uniform cable winding and product quality.

Comprehensive Safety Mechanisms

Designed with door interlocks, centrifugal brake systems, wire break detection, overload monitoring, and visual alarm indicators, this machine maximizes operational safety.

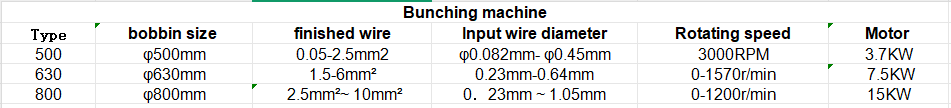

Technical Specifications

Product Advantages

Smooth Cable Routing: Swing-arm cradle and ceramic-guided spring steel twisting bow support stable and tangle-free cable processing.

Advanced Material Handling: The electro-hydraulic lifting system streamlines spool loading and unloading, reducing labor intensity.

Energy-Efficient Design: Intelligent power management and on-demand lighting and ventilation help minimize energy consumption.

Precision Engineering: High-frequency hardened surfaces and 40Cr alloy spindle with HB250 hardness ensure long-term performance and low wear.

Full Production Traceability: Built-in database logs critical production data for quality control, compliance, and operational transparency.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost